Precision Machining

Profile grinding is also known as projection, form, and copy grinding. In this process, a workpiece is projected at a magnification of 20 times onto a product shape drawing that is projected in advance like a shadow picture. A grinding wheel is operated by numerical control (NC) or manual control, and copy grinding is performed with the workpiece overlaid onto the projected drawing. Profile grinding, in which a workpiece is projected under magnification, creates a fine, high-accuracy shape.

Because we have seven profile grinding machines that can perform cylindrical grinding, we can perform high-accuracy groove grinding (caliber grinding) of mill rolls and manufacture acute-angled slitter blades (with a blade angle of 10°, an outer diameter of 100 mm, and a thickness of 1 mm), punching blades, small industrial blades, and cores for electroplated grinding wheels by utilizing rotational deflection control technology.

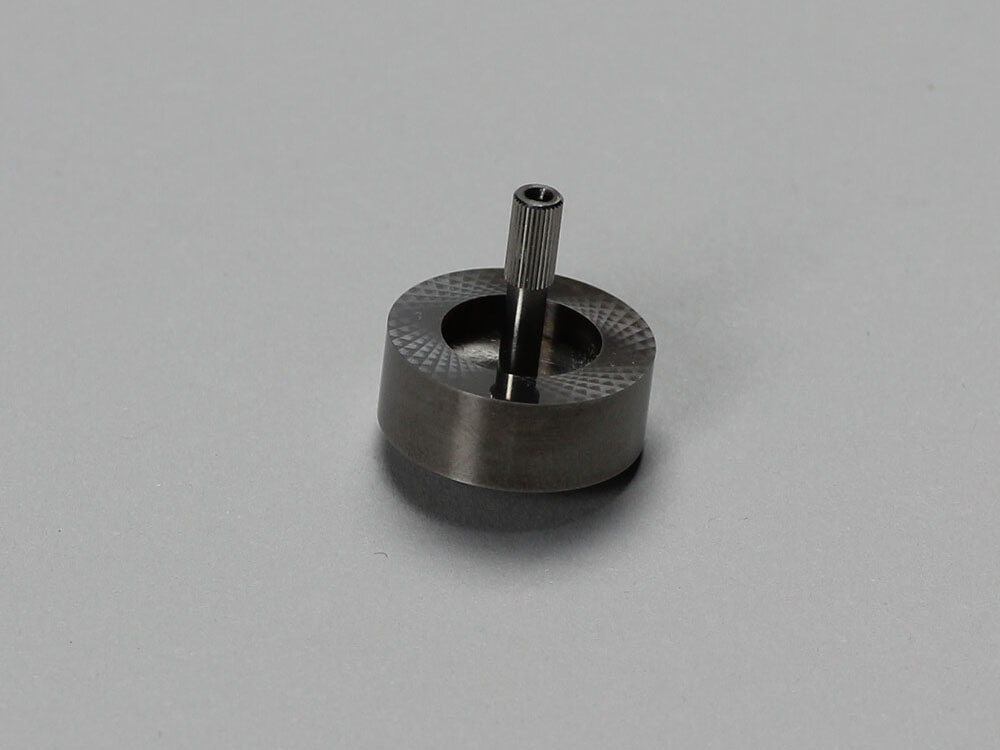

For enhancing and demonstrating the level of processing technology, we started the fabrication of precision tops. Although they are generally fabricated using an automatic computerized numerical control (CNC) lathe (automatic lathe) and finished with a cutting process, we finish them using a profile grinding machine. We are working hard on the prototyping, testing, and research of precision tops that keep on spinning for a long time alone.

【Head Office/Plant】

113-1 Enoshima-cho-Yasugi-shi,

Shimane-ken, 692-0057 Japan

FAX:+81-854-23-1403

【Tokyo Sales Office】

JRE Shiba-2-Chome Daimon Building 3F3-3 Shiba 2-Chome,

Minato-ku, Tokyo 105-0014 Japan

FAX:+81-3-5765-7507